Why IP rating matters for warehouse lighting

Similar to: https://trello.com/c/DZdVT5Ia/5042-rl-blog-what-is-the-best-ip-rating-for-outdoor-lighting

A warehouse primarily has one purpose: to stock and store goods. It sounds simple, but for most companies, the inventory is essential to the business. The items inside the warehouse directly correlate with revenue. The amount of stock shipped in and out are a sign of how well the company is performing.

Lighting can play a critical role in the function of a warehouse, so it's important to make sure it's well sourced and well maintained. One specification to pay attention to when you're purchasing lighting for warehouses is the IP rating.

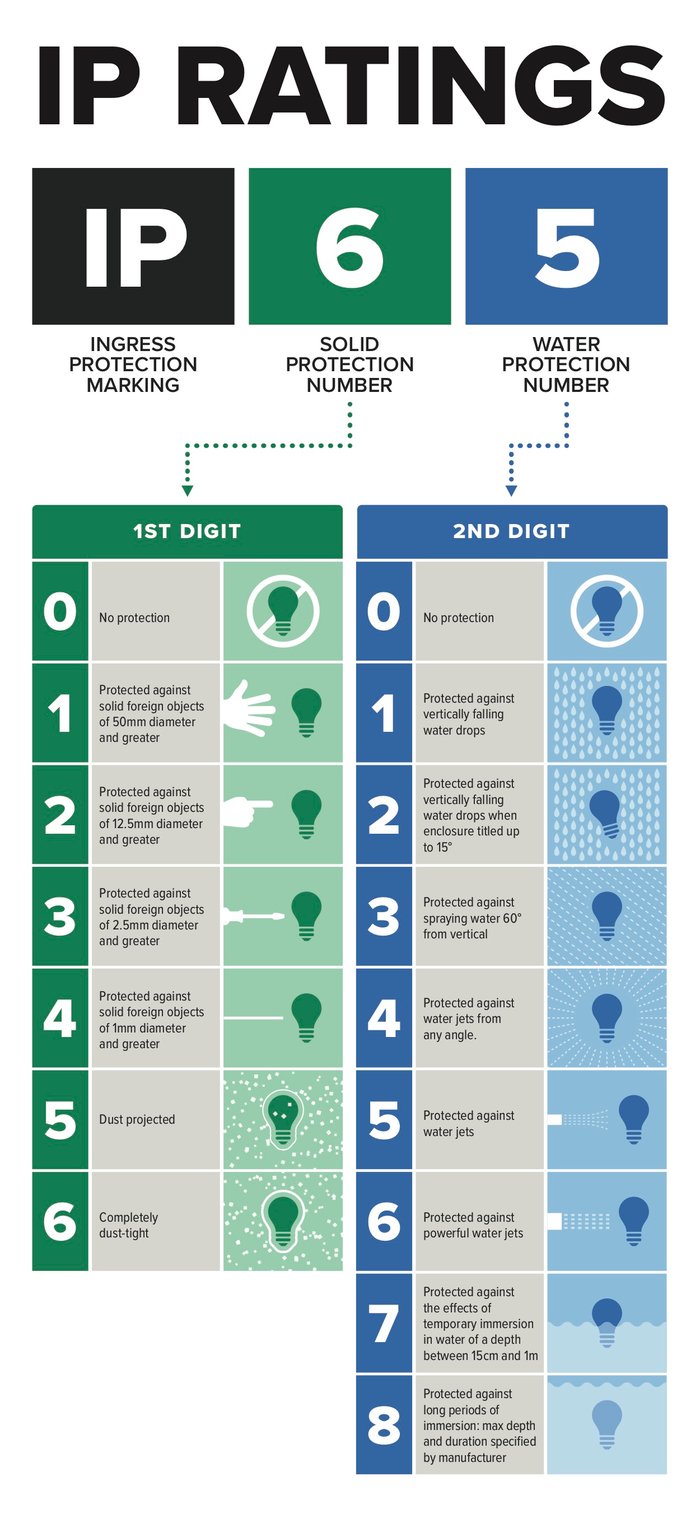

IP rating stands for Ingress Protection. What exactly does that mean? The Ingress Protection (IP) rating declares how well a fixture or bulb protects against outside elements, like dirt and water.

An IP rating will always have two numbers. The first number represents how well the product protects against solid objects, like dirt, dust, and bugs. The second number represents how well the bulb or fixture protects against liquids, like water. The higher the value of either digit, the tighter the protection.

Think of it this way: an IP rating helps you determine whether or not a fixture is durable enough to withstand the environmental factors of a specific area (such as a warehouse). And while most warehouses mostly don't have to worry about protection against water, there is a high likelihood of dust and bugs around the high bay light fixtures.

Why is IP rating important for warehouses?

Lighting is critical for warehouses because it can directly impact productivity. When fixtures are not well protected, they can easily become dirty, like in the images below. The result — dark, dingy lighting that can cause eye strain, a decrease in production, and other potential hazards.

If that's not reason enough, here are four other reasons to consider a higher IP rating for warehouse lighting:

1. Maintenance. When dust and bugs get into lights, it only increases the amount of maintenance needed to keep fixtures clean. Reducing the amount of maintenance on high-bay lighting because of dust seems like it's a worthwhile investment — especially if you need a lift.

2. Light output. When dust and particles build up inside fixtures, light output can be impacted. Too many layers of build-up can block and degrade light, like you see in the image above.

3. Appearance. Fixtures with a lot of build-up just look dirty — and that never leaves a good impression. Whether employees or visitors are primarily in your warehouse, appearance is important.

4. Productivity - Poor lighting may impact productivity and may also cause efficiency for employees to decline. It's hard to read labels correctly or operate equipment like forklifts when it's hard to see. Fixtures with a higher IP rating that block out dust and bugs may increase productivity over the long haul.

Best IP rating for warehouse lighting

Lower IP ratings (below IP44) are typically suited for indoor applications, but in spaces like warehouses where dust and other particles can easily enter fixtures, a higher IP rating (above IP44) should be considered. Any dust or debris can impede product operation or safety.

While IP ratings of IP44 and above are acceptable for indoor use, the best IP rating for warehouses is IP65. An IP rating of IP65 or high will limit the chance of exposure to dust, dirt, and debris and provide the most protection.

Upgrading warehouse lighting

When you're ready to upgrade warehouse lighting, IP rating is an important spec to pay attention to, but it's not the only one.

We recently worked with a manufacturing company that had more than 700 high-bay fixtures with more than 4,000 fluorescent tubes, but the space was still dark and maintenance was intense. An LED upgrade improved light quality and light levels, but also improved quality control in production. Read the entire story for the full results.

If you'd like to see the same results, contact us for a free lighting consultation. Our team of experts has nearly 40 years of experience in the lighting industry and strong partnerships with trusted manufacturers.